En Steneg, nos tomamos muy en serio la tecnología y lo que representa. Sabemos que la calidad industrial y la inspección son fundamentales para sectores que requieren precisión, fiabilidad y control continuo. Desde sistemas de visión y sensórica avanzada hasta instrumentación de alta precisión, estas tecnologías impulsan la innovación en automoción, salud, defensa y fabricación avanzada.

Para seguir avanzando, las empresas necesitan profesionales con un dominio técnico excepcional y capacidad para evolucionar en entornos multidisciplinares. En nuestra firma, conectamos compañías con expertos en metrología, control de calidad e inspección inteligente, asegurando que cada perfil seleccionado marque la diferencia en el sector.

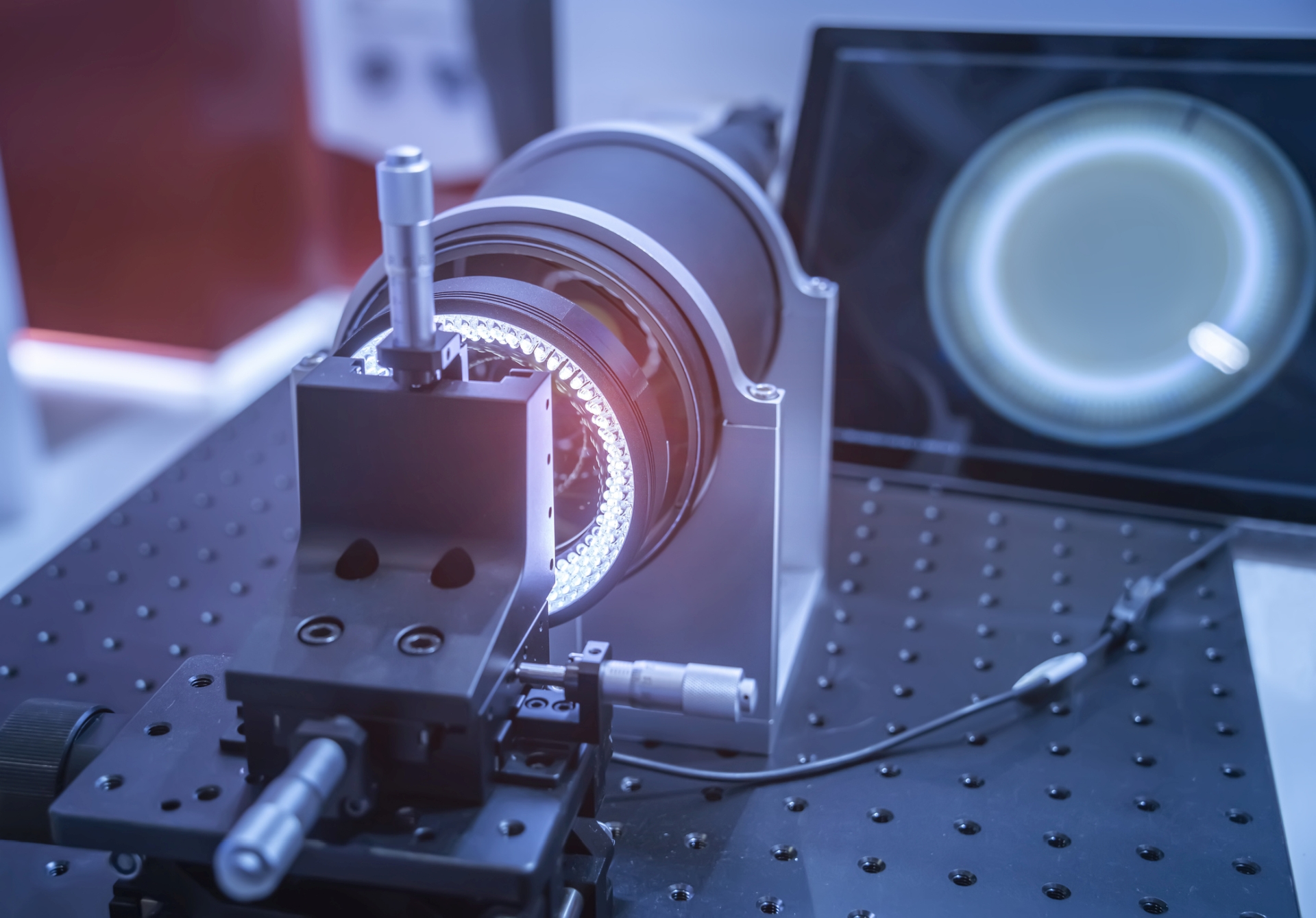

Estos sistemas permiten realizar verificaciones en tiempo real directamente en línea de producción. Combinan cámaras industriales con iluminación estructurada, sensores 3D y algoritmos de procesamiento de imagen, muchas veces potenciados por redes neuronales profundas.

Tecnologias principales:

-

Visión 2D y 3D con cámaras de alta resolución, escáneres de línea o sensores estéreo

Requiere conocimientos específicos en: configuración óptica avanzada (telecéntricas, filtros de banda estrecha), calibración extrínseca/intrínseca, compensación de distorsión y gestión precisa de iluminación en condiciones industriales. Estos conocimientos son fundamentales para garantizar resultados fiables en entornos productivos con alta variabilidad.

-

Deep Learning para

clasificación de defectos superficiales y segmentación semántica

Demanda habilidades técnicas complejas en: arquitecturas CNN/UNet/SegNet, entrenamiento con datasets desequilibrados y uso de técnicas como transfer learning y augmentación sintética. Estas competencias son esenciales para lograr modelos robustos en entornos con defectología diversa y escasez de datos etiquetados.

-

Análisis multiespectral

Aplicación avanzada que exige: integración de sensores multispectrales, calibración cruzada espectral, y análisis multivariante (PCA, PLS-DA) aplicado a detección de contaminantes y cambios químicos. Este tipo de análisis permite detectar propiedades invisibles al espectro visible, crítico en sectores como alimentación o farmacéutica.

-

Edge computing para

procesamiento local con baja latencia

Implica competencias poco comunes en: desarrollo sobre Jetson, AGX Orin, uso de CUDA y pipelines aceleradas. Integración con sistemas industriales mediante protocolos deterministas (EtherCAT, TSN). Este enfoque permite tomar decisiones en milisegundos, imprescindible en procesos de alta velocidad.

Aplicaciones clave:

- Inspección de soldaduras

- Verificación de etiquetas

- Detección de partículas.

- Medición de tolerancias en producción continua

La metrología óptica permite realizar mediciones sin contacto, con precisión submicrométrica, incluso en entornos industriales exigentes. Desde geometría 3D hasta propiedades ópticas y superficiales, estas tecnologías permiten un control dimensional fiable directamente en línea de producción.

Tecnologías principales:

-

Interferometría de luz blanca y láser

Requiere dominio técnico en: análisis de fase (PSI, WLI), compensación de aberraciones ópticas y gestión de estabilidad térmica y vibratoria para lograr precisión nanométrica. Fundamental en la inspección de superficies ópticas o componentes de alta precisión.

-

Triangulación láser y cámaras ToF para perfiles 3D

Aplicación técnica que necesita: calibración dinámica, compensación de errores por ángulo de incidencia y análisis de señal para minimizar ruido por reflectancia variable. Clave para garantizar estabilidad en materiales reflectantes o superficies irregulares.

-

Escaneo estructurado (fringe projection)

Uso especializado que implica: recuperación de fase con transformadas de Fourier, modelado 3D mediante ICP avanzado y alineación de múltiples vistas en inspección en línea. Permite obtener modelos tridimensionales precisos sin contacto en piezas complejas.

-

Fotogrametría industrial

Requiere experiencia específica en: uso de GOM Inspect, Metrolog X4 y fusión de datos multisensor. También exige conocimiento de normativas ISO/VDI para validación de precisión. Esencial para inspección de piezas de gran tamaño o validación in situ.

Aplicaciones clave:

- Control de geometría en componentes metálicos y plásticos

- Medición de espesor en films o cristales

- Alineación óptica de piezas en fabricación automatizada

Las técnicas NDT permiten evaluar la integridad estructural de materiales y componentes sin dañarlos. Con la digitalización industrial, se combinan con análisis por imagen y aprendizaje automático para ofrecer diagnósticos automáticos y modelos predictivos fiables.

Tecnologías principales:

-

Ultrasonidos por contacto y phased array

Implica competencias avanzadas en: uso de Full Matrix Capture (FMC), Total Focusing Method (TFM) y modelado FEM de propagación acústica en materiales anisotrópicos. Esenciales en aeronáutica y energía para la detección temprana de fallas internas.

-

Corrientes de Foucault

Requiere conocimientos técnicos precisos en: diseño de bobinas, simulación electromagnética y análisis multicanal en dominio de frecuencia. Indispensable para inspecciones rápidas en materiales conductores sin contacto físico.

-

Termografía activa

Aplicación que exige: interpretación térmica dinámica, análisis de mapas térmicos y correlación con defectología superficial y sub-superficial. Vital en la detección de delaminaciones o fisuras en materiales compuestos o electrónicos.

-

CT industrial con detectores planos

Requiere capacidades técnicas avanzadas en: configuración de exposición, reconstrucción volumétrica (SART, FDK), análisis CAD-to-CT y segmentación automática. Permite inspección interna con una resolución sin precedentes.

-

IA para análisis NDT

Necesita dominio en: redes profundas para detección y clasificación de defectos internos, entrenamiento supervisado con imágenes NDT complejas. Crítico en sectores con grandes volúmenes de datos como ferroviario o automoción.

Aplicaciones clave:

- Análisis estructural en aeronáutica

- Inspección de soldaduras

- Detección de corrosión interna

- Verificación de materiales compuestos

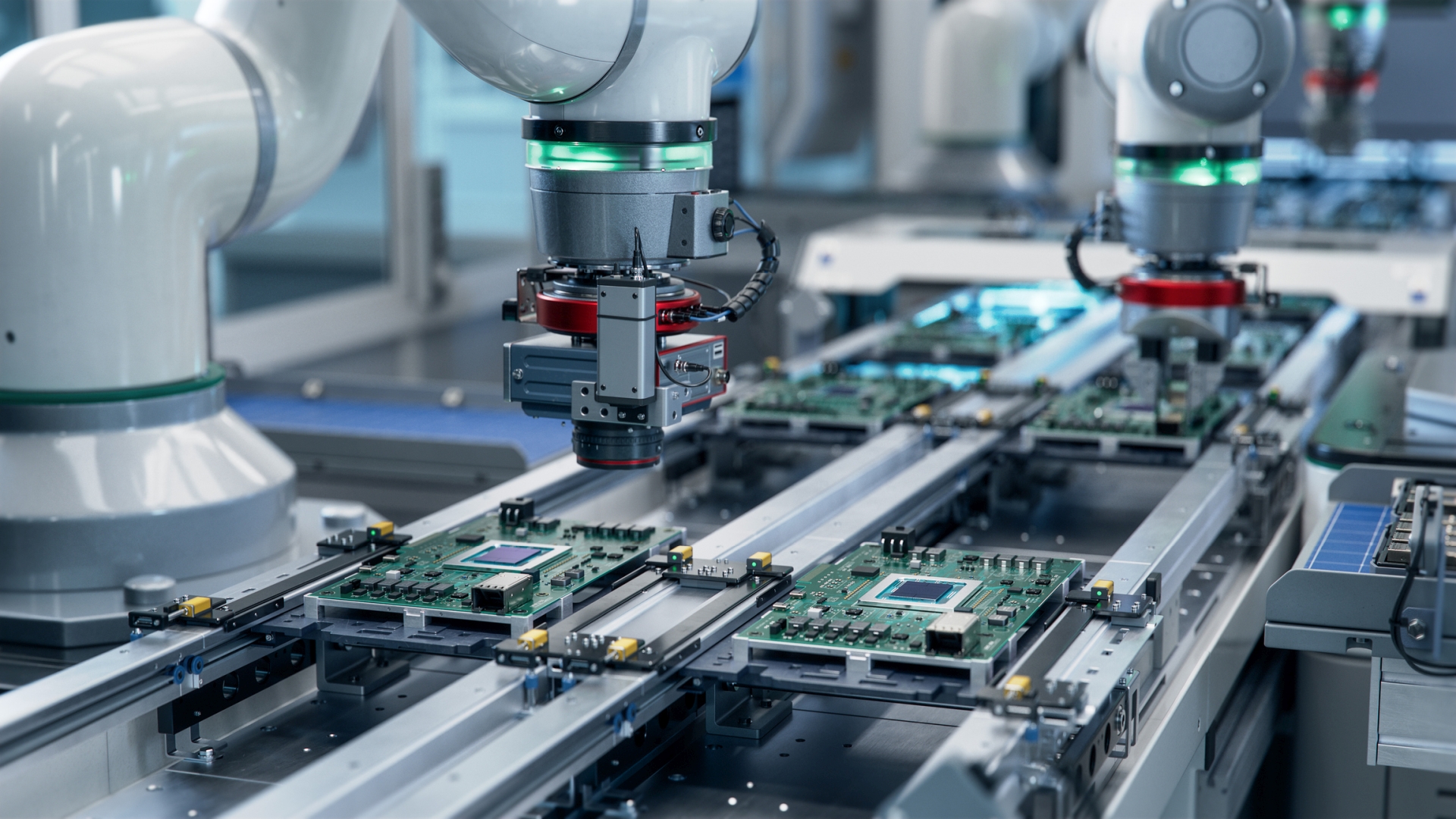

La integración de sensores ópticos y electrónicos en sistemas embebidos permite construir dispositivos inteligentes capaces de monitorizar en tiempo real parámetros clave del proceso o del producto, incluso en entornos industriales exigentes.

Tecnologías clave:

-

Sensores espectrales e hiperespectrales

Tecnología especializada que requiere: configuración óptica difractiva, calibración espectral, análisis multivariante (ICA, PCA) y extracción de características para clasificación de materiales. Clave para el control de calidad sin contacto en sectores como farma o reciclaje avanzado.

-

FPGA y SoC (System-on-Chip)

Requiere alto nivel de especialización en: programación en VHDL/Verilog, uso de Zynq UltraScale+, optimización de pipelines de visión con lógica embebida y gestión avanzada de DMA. Fundamental en aplicaciones donde velocidad y eficiencia energética son críticas.

-

Sensores CMOS y CCD industriales

Demanda experiencia técnica en: adquisición en tiempo real, diseño de buffers de imagen, sincronización con triggers externos y control de exposición dinámico. Permite capturas precisas en entornos complejos y con alta exigencia temporal.

-

Interfaces industriales (EtherCAT, CAN, OPC-UA)

Tecnología crítica que requiere: integración de sensores y actuadores en redes deterministas, configuración de nodos y sincronización cíclica. Esencial para un control robusto y fiable en líneas de producción interconectadas.

Aplicaciones clave:

- Visión autónoma en maquinaria

- Detección de contaminantes

- Sensores embebidos en robots colaborativos

- Medición de parámetros en entornos adversos

Nuestra visión se complementa con una participación activa en los principales eventos internacionales, donde se presentan innovaciones, se intercambian casos de uso reales y se fortalece el ecosistema de inspección y calidad industrial.

Eventos de referencia:

- Control Stuttgart (Alemania) – Tecnologías de QA, metrología y visión artificial

- Automate (Chicago) – IA, automatización y robótica aplicada

- The Vision Show (Boston) – Últimas soluciones en visión por computador

- Quality Expo (Nueva York) – Metrología y testing industrial

- Mindtech (Vigo) – Industria metalúrgica y tecnologías avanzadas

- BIEMH (Bilbao) – Automatización y control en fabricación

- EMAF (Oporto) – Industria y control de calidad en el sur de Europa